Cluster picking¶

Cluster picking is an advanced picking method that combines the efficiency of batch picking with immediate sorting during the picking process. It is best suited for warehouses with high order volumes where organization and speed are critical.

Unlike batch picking, which requires a separate sorting step after picking, cluster picking sorts items directly into designated bins or containers for each sales order (SO). This eliminates the need for post-picking consolidation, making it ideal for operations prioritizing speed and accuracy.

Cluster picking is particularly effective in environments where immediate organization is crucial, and orders contain a mix of items that need precise sorting during, rather than after, the picking process.

However, cluster picking does have some disadvantages. For instance, urgent orders cannot be prioritized, and optimized batches must be manually created beforehand. As a result, the picking process can lead to bottlenecks.

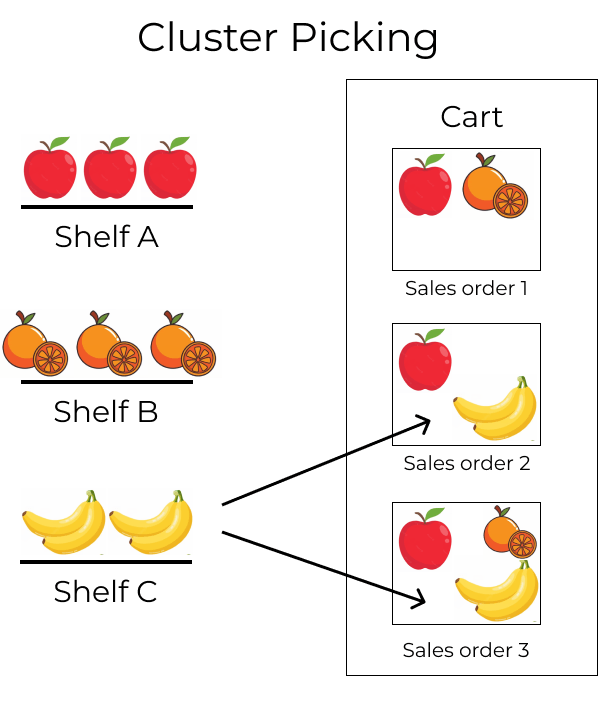

Example

|SO| 1 calls for one apple and orange

|SO| 2 calls for one apple and banana

|SO| 3 calls for one apple, orange, and banana

Apples are stored in Shelf A, oranges in Shelf B, and bananas in Shelf C.

To pick products for three orders at once, the cart is loaded with three empty packages.

Starting at Shelf A, the picker places apples into each package. Next, the picker navigates to Shelf B, and places oranges in the packages designated for |SO| 1 and |SO| 3. Finally, the picker pushes the cart to Shelf C, and loads packages for |SO| 2 and |SO| 3 with a banana, each.

With the packages for all three |SOS| packed, the picker pushes the cart to the output location, where the packages are sealed and prepared for shipment.

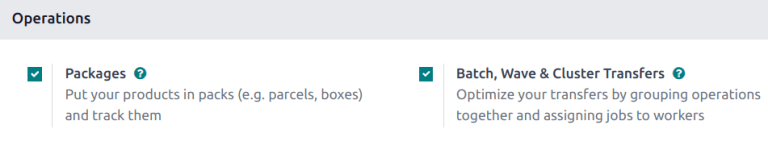

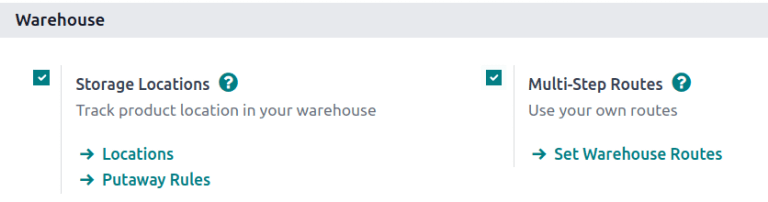

Cấu hình¶

To enable cluster picking, begin by navigating to . Under the Operations heading, activate the Packages and Batch, Wave & Cluster Transfers options.

Since batch picking is used to optimize the pick operation in Odoo, the Storage Locations and Multi-Step Routes options, under the Warehouse heading, must also be checked on this settings page.

Storage locations allow products to be stored in specific locations they can be picked from, while multi-step routes enable the picking operation itself.

When finished, click Save.

Packages setup¶

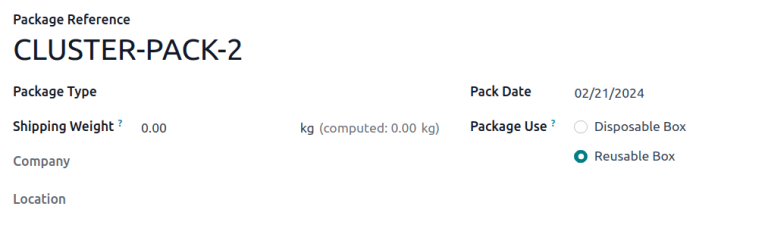

To configure the containers to be used during the picking process, navigate to . Click the New button to create a new package.

On the new package form, the Package Reference is pre-filled with the next available

PACK number in the system. Pack Date is automatically set to the creation date of the

form.

Set the Package Use field to Reusable Box.

Xem thêm

Example

A package intended for cluster picking is named CLUSTER-PACK-3 for easy identification. For

this workflow, the products are directly packed using their intended shipping boxes, so

Package Use is set to Reusable Box.

Create cluster batch¶

To create a cluster, navigate to and select the operation type card, Delivery Orders or Pick (whichever is the first operation in the delivery flow).

Ghi chú

Cluster pick batches can be created for outgoing shipments in one, two, or three steps.

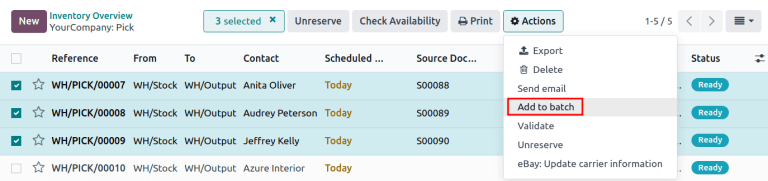

Click the checkbox to the left of the corresponding outgoing operation to add them to the batch. With the desired pickings selected, click the Actions button, and select the Add to batch option from the resulting drop-down menu.

Example

To create a cluster batch, as shown in the example above, in a warehouse configured with two-step outgoing shipments, the following pick operations are selected:

WH/PICK/00007: linked to |SO| 88 for one apple and orange.WH/PICK/00008: linked to |SO| 89 for one apple and banana.WH/PICK/00009: linked to |SO| 90 for one apple, orange, and banana.

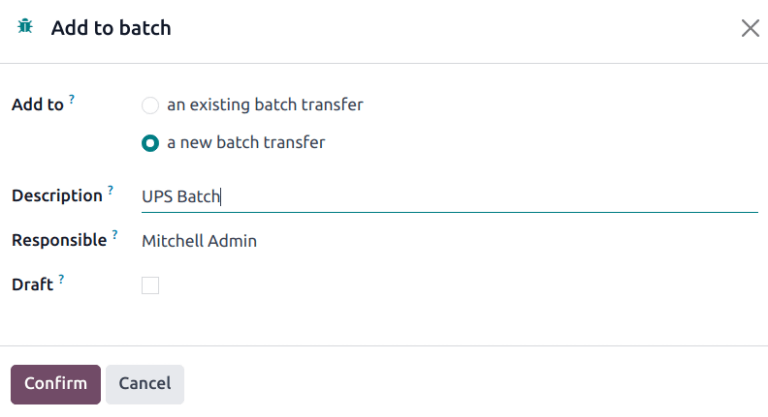

Doing so opens an Add to batch pop-up window, wherein the employee Responsible for the picking can be assigned.

Choose from the two options in the Add to field to either: add to an existing batch transfer, or create a new batch transfer.

Then, add a Description for this batch.

Mẹo

The Description field can be used to add additional information to help workers identify the source of the batch, where to place the batch, what shipping containers to use, etc.

To create draft batch pickings to be confirmed at a later date, select the Draft checkbox.

Conclude the process by clicking Confirm.

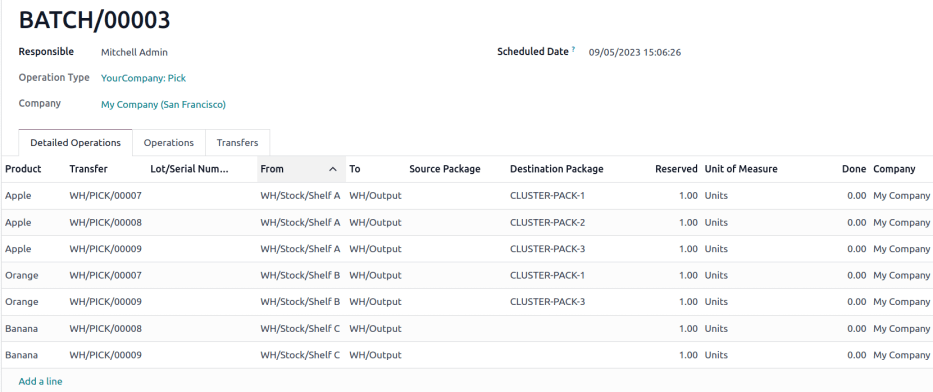

Process batches¶

To process batches, navigate to . Click on a batch to select it.

In the Detailed Operations tab, products that are to be picked are grouped by location.

Set the Destination Package to the package dedicated to that particular order.

Example

Process the cluster batch for the three orders of apples, oranges, and bananas example by assigning each picking to a dedicated package.

At the storage location for apples, WH/Stock/Shelf A, assign the apples in all three pickings

to one of the three reusable packages, CLUSTER-PACK-1, CLUSTER-PACK-2, or CLUSTER-PACK-3.

Record this in Odoo using the Destination Package field in the Detailed Operations tab.