Manufacture with lots and serial numbers¶

In Odoo, lot numbers and serial numbers are used to identify and track products in Odoo. Serial numbers are used to assign unique numbers to individual products, while lot numbers are used to assign a single number to multiple units of a specific product.

When manufacturing products tracked using lots or serial numbers, Odoo requires the lot or serial number to be assigned to each product before manufacturing can be completed. This ensures that each product is properly tracked from the moment it enters inventory.

Configure products for tracking¶

By default, Odoo tracks the quantity of each product on hand, but does not track individual units of a product. Lot or serial number tracking must be enabled for each product individually.

To track a product using lots or serial numbers, begin by navigating to , then scroll down to the Traceability section, and tick the Lots & Serial Numbers checkbox. Finally, click Save to save the change.

Next, click on , and select a product to track. Make sure the Track Inventory checkbox is ticked in the General Information tab. Since lot and serial number functionality is enabled, a drop-down menu appears next to the ticked checkbox.

Click on the Track Inventory drop-down menu. By default, By Quantity is selected, which only tracks the quantity on hand. Select By Lots to track the product using lot numbers, or By Unique Serial Number to track the product using serial numbers.

See also

Lot number manufacturing¶

To manufacture a product tracked with lots, begin by navigating to . Click New to create a new manufacturing order (MO).

In the Product field, select a product tracked using lots, and enter the desired Quantity. Click Confirm to confirm the MO.

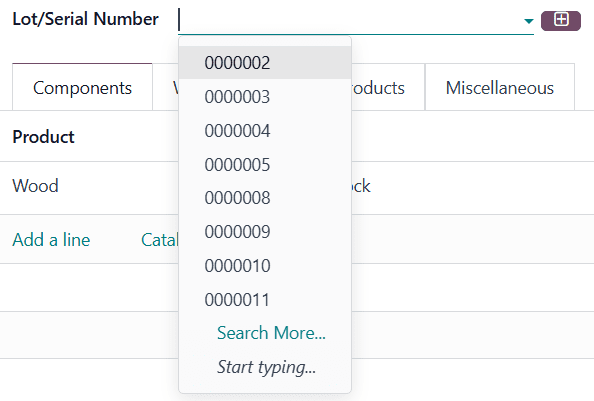

Once the MO is confirmed, a Lot/Serial Number field appears in the top section of the MO form. By default, this field is empty.

To populate the Lot/Serial Number field with a lot number, click the (plus) icon to the right of the field. Doing so automatically generates a lot, using the next available number, and enters it in the field.

Alternatively, click on the Lot/Serial Number field and select an existing lot number, or manually enter a new lot number and click Create “#” in the drop-down menu.

Either of these methods assign the product(s) in the MO a lot number before production is finished. It is also possible to complete production and close the MO by clicking Produce All, without assigning a lot number. Doing so automatically generates and assigns a lot, using the next available number.

Serial number manufacturing¶

To manufacture a product tracked with serial numbers, begin by navigating to . Click New to create a new MO.

In the Product field, select a product tracked using serial numbers, and enter the desired Quantity. Click Confirm to confirm the MO.

Once the MO is confirmed, a Lot/Serial Number field appears in the top section of the MO form. By default, this field is empty.

The rest of the manufacturing process depends on how many units the MO contains.

Manufacture single unit¶

If a single unit of the product is being manufactured, clicking Produce All closes the MO, and automatically generates and assigns the next available serial number, which appears in the Lot/Serial Number field.

To assign a serial number without closing the MO, enter a number manually in the Lot/Serial Number field, and click Create “#”, or click the (plus) icon to the right of the field to auto-fill it with the next available number.

Manufacture multiple units¶

Important

When manufacturing a product tracked using serial numbers, an MO can be created for multiple units. However, when serial numbers are assigned to each unit, either at the end of production or before, the MO is split into multiple MOs, each containing one unit of the product.

Each of the split MOs is identified by a numerical tag added to the end of the original MO number.

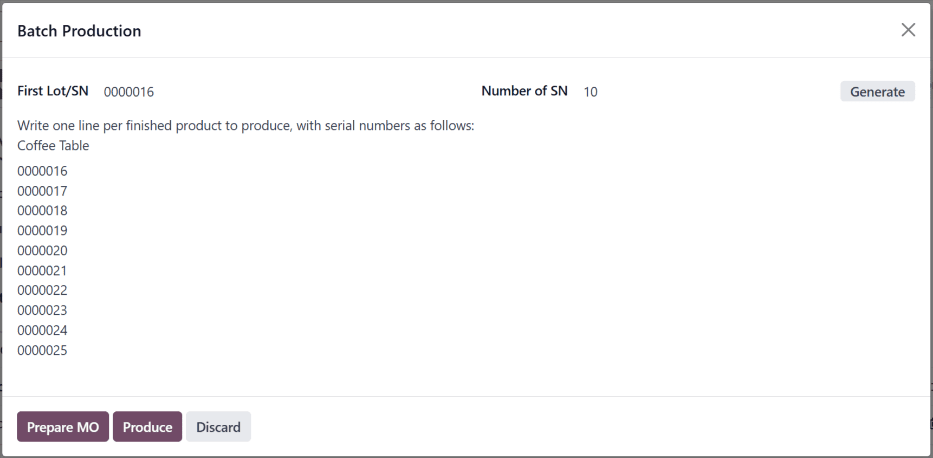

To assign serial numbers to each unit of an MO, click Produce All to open the Batch Production pop-up window.

The First Lot/SN field of the pop-up window is auto-filled with the next available serial number. The Number of SN field defaults to the number of units being manufactured. The values of either field can be changed manually.

Click Generate to generate the specified number of serial numbers, beginning with the number entered in the First Lot/SN field. The serial numbers are displayed in the text box at the bottom of the pop-up window, and can be manually changed after generation.

To assign serial numbers without completing production, click the Prepare MO button. Doing so splits the MO into individual MOs, one for each unit in the original MO. Each MO is left open, and can be closed individually.

To assign serial numbers and complete production, click the Produce button. Doing so splits the MO into individual MOs, one for each unit in the original MO. All of the MOs are closed, since production is complete.

After clicking Prepare MO or Produce, the app

automatically shows the first of the split MOs (ex. WH/MO/00109-001). To view and access the

rest the split MOs, click the Backorders smart button at the top of the screen.